🤖 I write about robots

London, England

Joined November 2012

- Tweets 3,173

- Following 3,850

- Followers 9,565

- Likes 5,121

Pinned Tweet

Thread: How China bought Germany's robotics crown jewel

Quick story: I recently called Kuka German in a thread and got called out - "Kuka is Chinese now."

This sent me down a rabbit hole.

What I found was straight out of Succession, and it reshaped how the West thinks about tech sovereignty.

This is the story of how a Chinese appliance company bought Kuka & kick-started China's robot dominance. ⬇️

Jack 🤖 retweeted

It doesn’t look like much.

But this small robot from Stanford might do for robotics what the Apple II did for computing...

make it personal. 🧵

[📍 Save this... you’ll want to remember his name.]

Jack 🤖 retweeted

🧵How SoftBank spent billions trying to shape the future of robotics.

From cute humanoids to warehouse takeovers, its strategy has been bold, messy, and strangely influential.

Let's find out how it happened.

[Save this thread for later 📌]

AGI in robotics isn't about intelligence - it's about getting the job done after one of the 10,000 ways something can go wrong happens.

Why use a lever arm instead of a bowl feeder?

🔩 What it's doing:

Feeding screws from bulk into an assembly line using a simple lever arm mechanism that scoops and orients parts.

⚙️ How it works:

The lever sweeps through the pile of screws, picks a few, and delivers them to the next station, pre-aligned. Gravity and the arm's geometry handle basic orientation.

🎯 Why this approach:

Bowl feeders are more typical for this application but they're expensive, noisy, sensitive to part geometry, and a pain to changeover.

This lever arm is dead simple – works with different screw sizes, easy to adjust, minimal maintenance.

It also looks like the cycle time is faster than a typical bowl as it can pick multiple bolts at once.

What would you use? Vibratory bowl? Vision-guided pick? Stick with the lever❓

Jack 🤖 retweeted

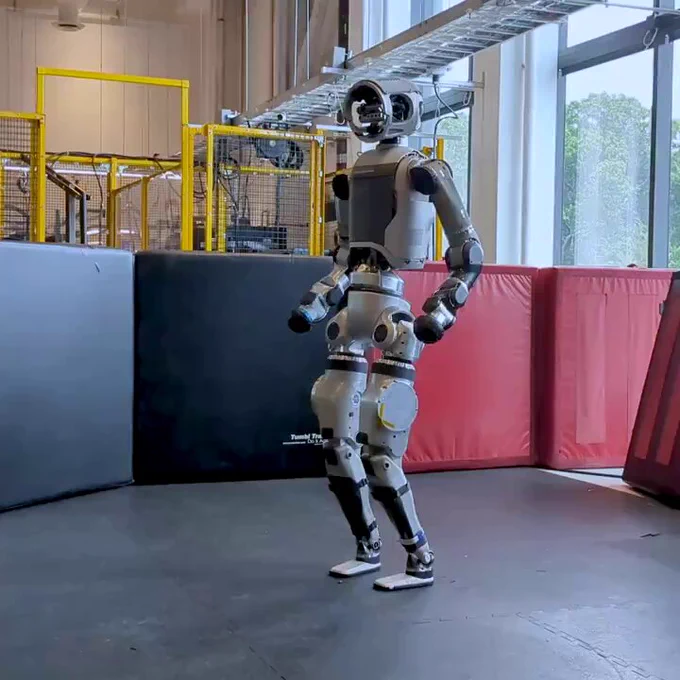

Humanoids this, humanoids that….

But when you strip away the hype, THIS is what a humanoid really is — 21 joints talking over RS-485, each motor balancing power, precision, and timing.

Intelligence is the easy part. Control is the hard part.

Source: @UnitreeRobotics

Every robot startup should have a Slack channel called "why-did-it-fail-today."

Best way to improve is obsese over the edge cases

Classic problem: The robot works perfectly with version 2.1.3 of the firmware but your customers are running 2.1.2, 2.1.4, and one running 1.9.7.

Jack 🤖 retweeted

We're currently:

- Hiring mechanical, software, and ML engineers

- Looking for angel investors experienced in robotics and US manufacturing

- Looking for US manufacturing partners

Please let us know anyone we should talk to! 🚀🚀🚀 :)

Email: jx@gradientrobotics.ai

Jack 🤖 retweeted

We’ve inherited the K-Scale spirit, mission, and core engineering team at @gradientrobots

We closed our pre-seed round in Sept and we’re accelerating fast 🚀

We're building U.S.-manufacturable robots at scale. WE'll be the open-source Unitree for America

Join us! We're hiring

Jack 🤖 retweeted

A new startup, Gradient Robots, has been announced, founded by K-Scale's core engineering team, with the mission to be "the open-source Unitree for America."

The former K-Scale COO says there are some behind-the-scenes reasons that made K-Scale a hard bet for investors.